AOM Hood: State-of-the-Art, Energy-Saving Kitchen Exhaust Innovation

Air & Odor Management (AOM) presents its breakthrough in Kitchen Exhaust System and Hood Design. The first-of-its-kind, state-of-the-art AOM Hood presents an innovative and energy-saving solution to mitigate kitchen exhaust environmental pollution and prevent kitchen exhaust duct work fire.

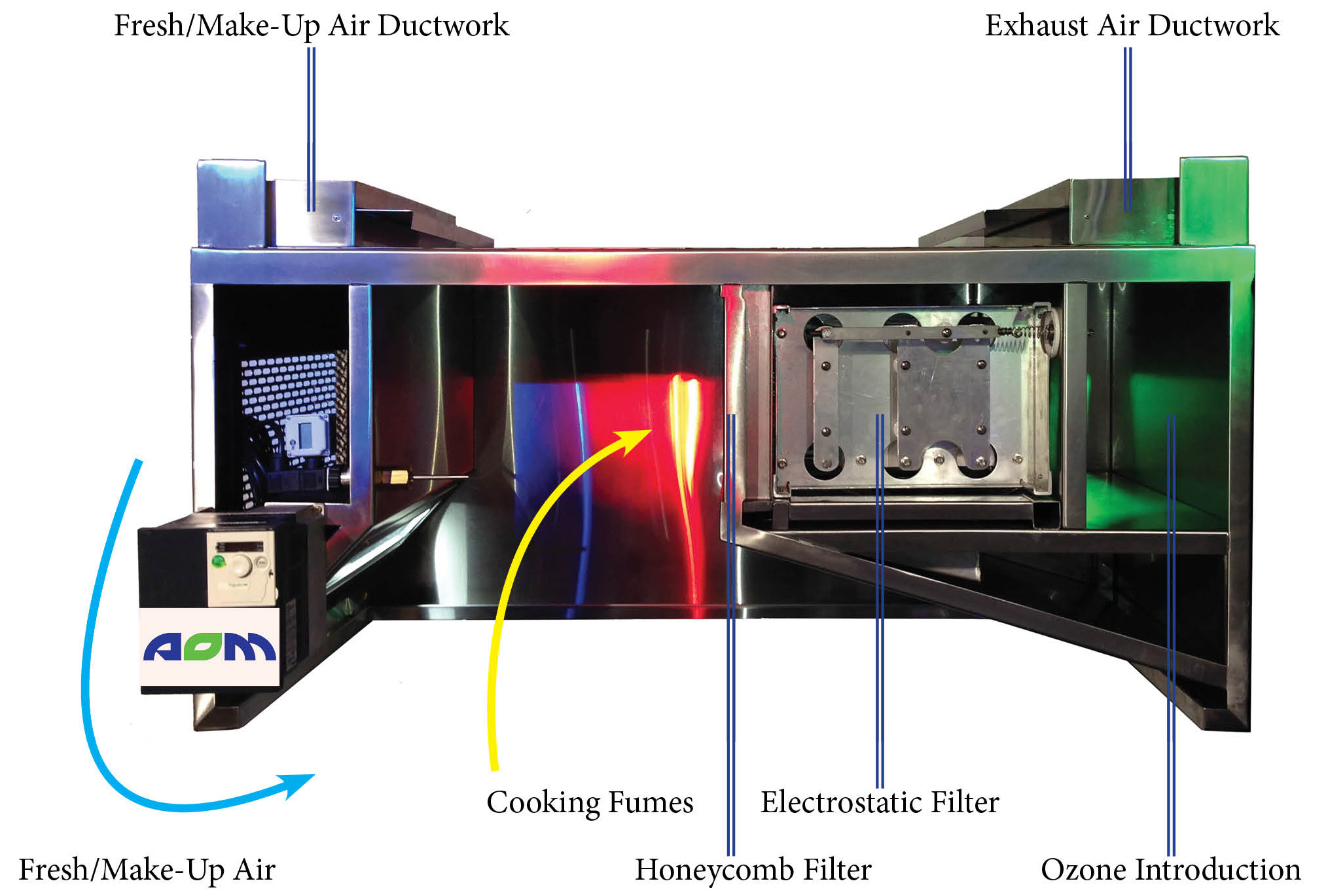

Made from high-quality stainless steel, the hood integrates flame-impeding honeycomb filters, electrostatic filters, and ozone generators to clean and treat smoke, oil and grease, and associated odors generated from cooking before discharge into the environment.

AOM’s high-efficiency, low-resistance stainless steel honeycomb filters acts as a pre-filter (filtering particulates down to 8 microns) as well as a flame barrier to prevent flame penetration into the kitchen exhaust duct work. In addition, it conforms to AS 1530.1 methodology for fire tests on building materials. The flame barrier test can be seen in the video below:

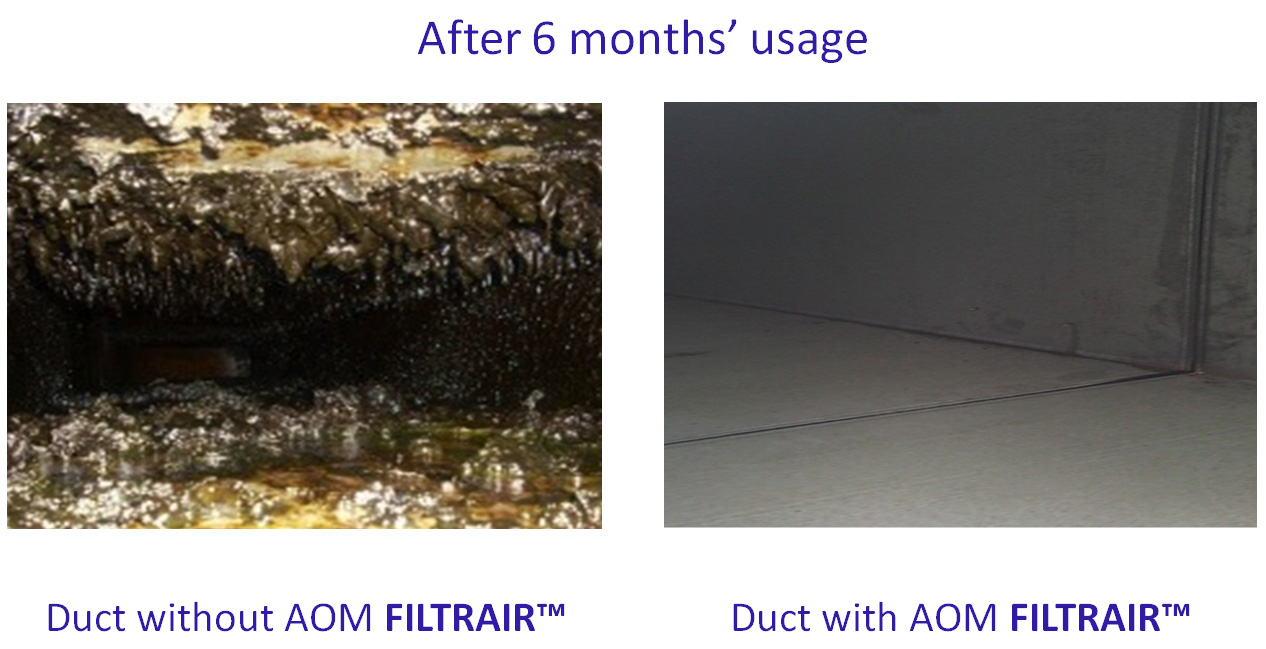

Electrostatic filters entrap oil and grease, and smoke particles (down to 0.01 micron) using Electrostatic Precipitation (ESP) technology, while ozone generators produce ozone to mitigate remaining odor in the airflow. This AOM FILTRAIR™ technology (Honeycomb Filters, Electrostatic Filters, Ozone Generators) has been tested (AS 1668.2-2012) to remove 98% of oil and grease, and smoke particles by The University of Sydney. A comparison of the internal cleanliness of a kitchen exhaust ductwork with and without AOM FILTRAIR™ technology 6 months after usage is shown below:

Furthermore, aside conventional calculation methods for kitchen exhaust airflow using the kitchen hood’s dimension, AOM’s proprietary hood design allows for kitchen exhaust airflow calculation to be based mainly on kitchen equipment placed underneath it. This allows for a reduction in airflow calculation by up to 40%, reducing the exhaust fan’s capacity as a result. Moreover, sensors can be installed to monitor the intensity of cooking under the hood so that airflow and ozone output can be automatically adjusted accordingly, further reducing energy consumption.

The AOM Hood will be exhibited together with other unprecedented kitchen exhaust innovations at Hotel Asia 2016, part of Food, Hotel Asia 2016 (FHA2016), at Singapore Expo from 12th-15th April 2016. Register your attendance and visit AOM at Hall 1, Booth 1A1-01 to find out more!